HYDROMOTIVE MIXED FOAM FIRE EXTINGUISHING FLUID TURBINATOR

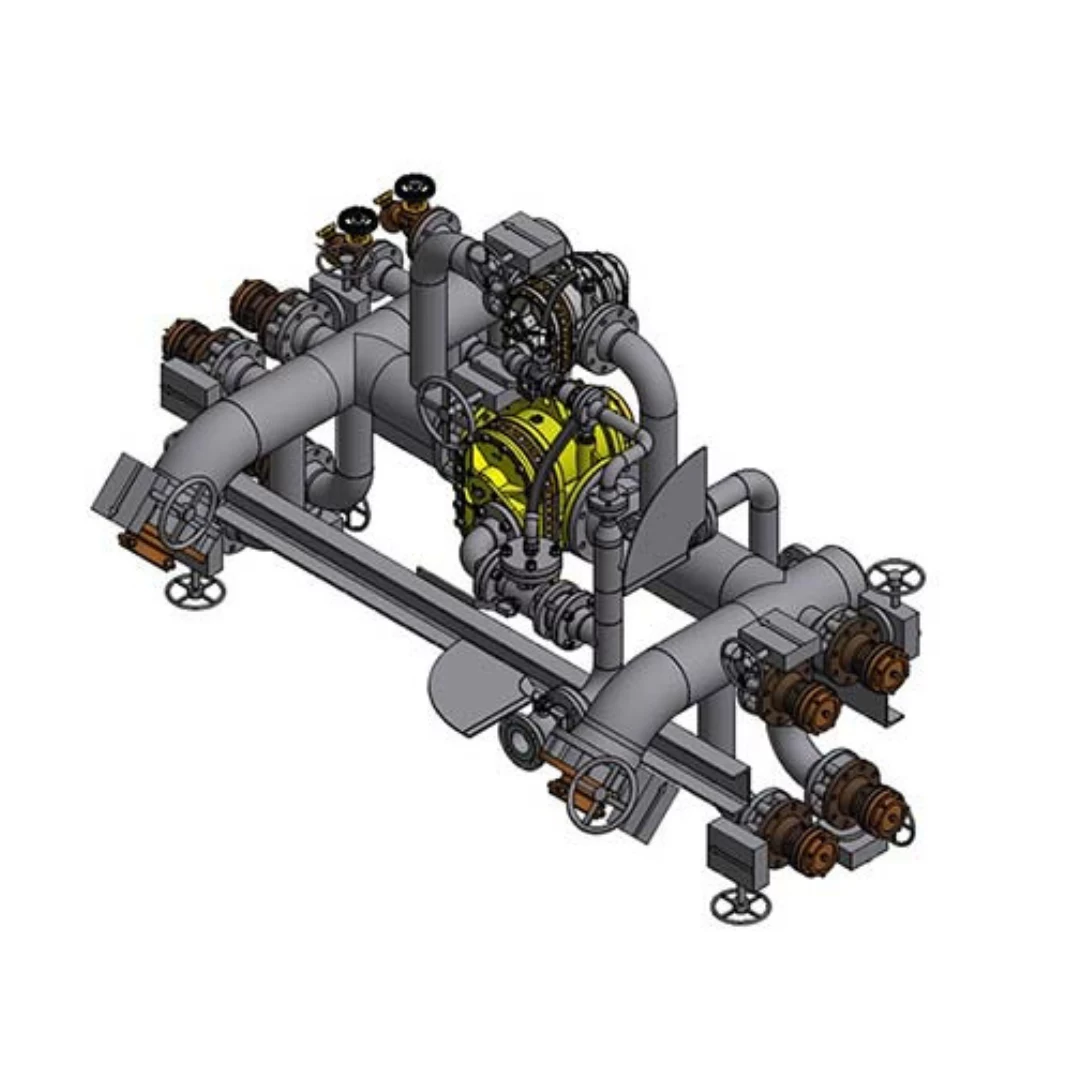

Suitable for use in both fixed systems and mobile firefighting units, the “Turbinator” mixer is designed to accurately mix liquid foam concentrate with either drinking water or seawater.

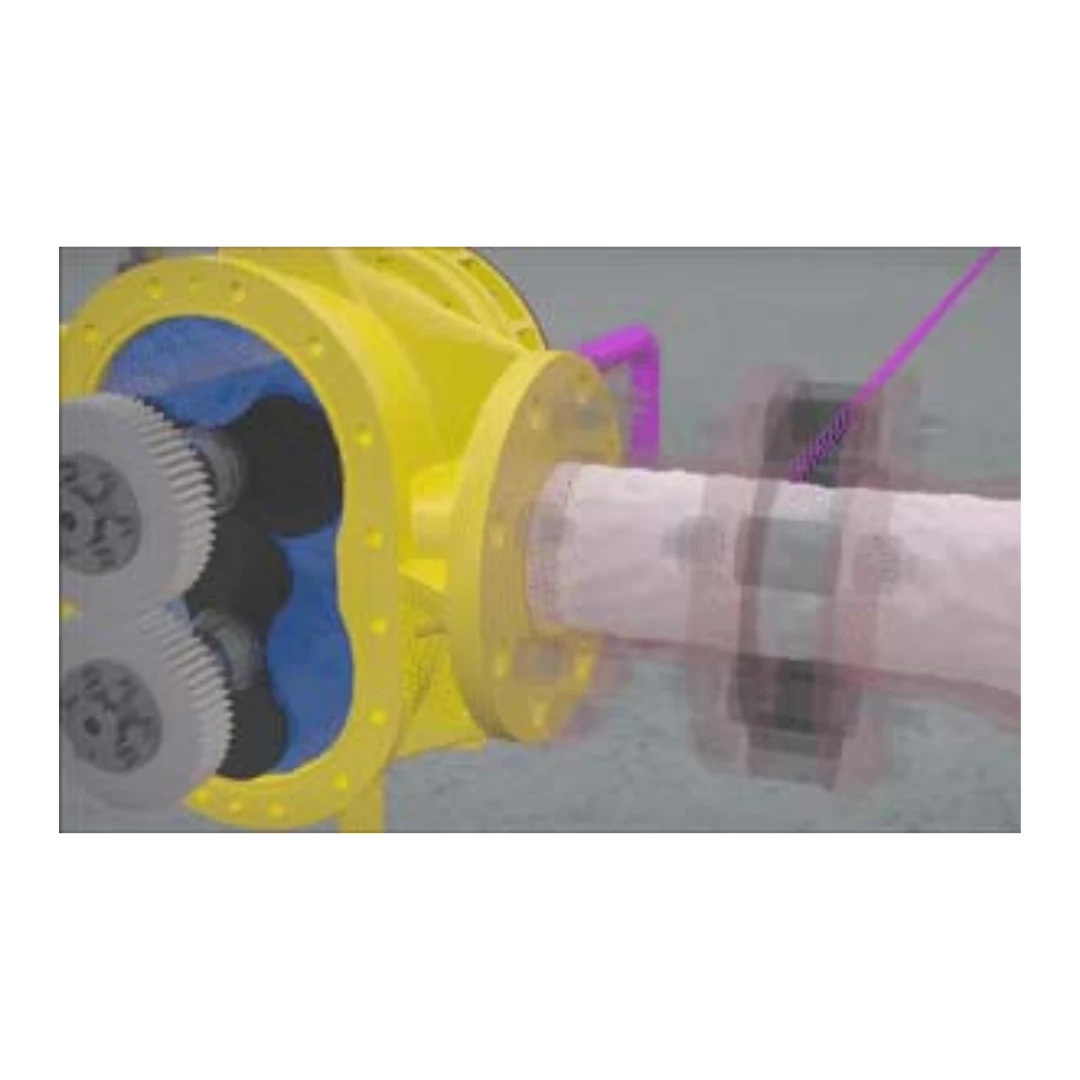

The Turbinator foam mixer is composed of two main parts: a water motor and a foam concentrate pump.

It has a variety of options of varying cross-section, according to the project requirement.

The hydro motor and the pump are interconnected and integrated within a single compact shell, acting as positive displacement pumps.

During the operation of the fire extinguishing system the water flow rotates the water motor. A specific, constant volume of water passes through the water motor during each rotation. The shaft of the hydraulic motor rotates the shaft of the pump, which similarly, at each rotation, allows a specific and constant volume of liquid condensate to enter.

In other words, regardless of the pressure or flow rate of the water in the system, this movement always obtains the ratio of water and liquid fire extinguishing concentrate mixture required for the correct production of foam solution.

Thanks to its unique design and gear drive transmission, the Turbinator foam mixer, develops a powerful (auto-filling) suction that results in a reliable and uninterrupted supply of foam concentrate.

COMPACT AND SIMPLE

The Turbinator foam mixer is particularly compact and is easily installed, without complicated requirements, in new or existing foam fire extinguishing systems.

It is specified, in accordance with NFPA20, that all permanent foam pumps must be able to operate "dry" for at least ten minutes.

Compliance with the requirement is critical to the certification and acceptance of this product.

The Turbinator foam mixer has a very high suction capacity, as well as tolerance to any air within the suction pipes, so no complicated procedures are required to start it up.

The Turbinator foam mixer is one of a kind. From the beginning it has been designed as fire fighting equipment, taking into account the specific needs and practices in fire fighting applications.

Knowsley SK's Turbinator foam mixer, is a precise positive displacement, positive displacement firefighting foam concentrate metering pump that uses the water in the firefighting system as an energy source, with a zero environmental footprint.

DESIGN & USES

PORTABLE EQUIPMENT – FIRE-FIGHTING VEHICLE EQUIPMENT

Thanks to its compact design, the Turbinator foam mixer can easily be operated as a portable unit, either by simply mounting it on a hand trolley and/or trailer or by integrating it into fire trucks.

The prefabricated systems available are designed to suit most applications, and there is the option of bespoke manufacture to suit the project requirement.

FIXED EQUIPMENT

The Turbinator foam mixer can be easily integrated into any existing or new permanent foam firefighting water supply system. Such as for example fuel storage tanks, refineries, power plants, use with fire cannons and many more.

MINIMUM NETWORK WATER PRESSURE LOSS

The Turbinator hydrokinetic foam mixer has the lowest pressure loss of any system on the market.

For a more detailed presentation of the fluid dynamic specifications and loss diagrams of the Turbinator foam mixer, contact P & K PAYLOU OE

(tel: 210 6845018, e-mail : info@pavlou.com.gr)

THE TURBINATOR FOAM MIXER IS MANUFACTURED FROM SELECTED MATERIALS OF HIGH SPECIFICATIONS TO ENSURE RESISTANCE TO CORROSION IN THE HARSHEST ENVIRONMENTS

UNIQUE TECHNOLOGY FOR DURABILITY

The integrated hydrofoils are made of flexible materials that have the unique mechanical property of absorbing vibrations, resisting any solid particles entering the hydro motor and exhibiting zero friction wear. In particular, the usual presence of solid particles found in fire water mains does not cause damage, as the hydro motor is designed to operate with two hollow water vanes that allow any potential dirt or rust to pass through the unit without clogging.

Also when starting the fire system, the over-speed of up to 120% that can occur does not damage the unit due to its robust design. At the same time, any air within the network piping does not cause any damage to the mixer, thus simplifying the start-up of the fire suppression system.

Finally, the pump meets the NFPA20 requirement for dry running.

FUNCTIONALITY

Prefabricated systems are available to suit most common firefighting applications, and there is also the possibility of designing a specialised system to meet specific requirements. The Turbinator foam mixer is safe for use in any ATEX environment as it does not require electricity or complex control circuits to operate. Provided a ready-made foam fire extinguishing system is in place, the mixer is ready for use.

MAIN TECHNICAL CHARACTERISTICS

- Safe for use in any ATEX environment

- Compact / ergonomic design

- No electrical supply or control circuit required

- Ease of installation – no special start-up procedures

- Minimal water pressure loss (low pressure drop)

- Variable flow

- Highly tolerant to overspeed

- Can be installed vertically or horizontall

THE MIXED TURBINATOR

- Have minimal maintenance requirements

- Options are available for use with drinking or salt water

- Available for 1% or 3% foam admixture, regardless of flow rate

- They are resistant to stress due to ingress of particles (e.g. rust)

- They are CE marked

- Meet the dry running requirement of NFPA20

- Have low noise emissions

THE PRODUCTS OF KNOWSLEY SK LIMITED BEAR THE SPECIAL CE MARKING IN THE CONTEXT OF DIRECTIVE 2006/42/EC AND DIRECTIVE 94/9/EC.

QUALITY CONTROL

TESTING AND SAMPLING OF LOTS

To ensure the correct processing of selected high quality materials, we maintain strict levels of testing, sampling and batch traceability. Together with our suppliers we have developed thorough testing programmes for each individual component and for systems as a whole.

Our highly qualified staff not only have a thorough and in-depth knowledge of KNOWSLEY products, but – just as importantly – also understand customer requirements.

We can assure you that all KNOWSLEY SK LIMITED products are manufactured in accordance with our stringent quality control procedures and we are ISO 9001 – 2015 certified.